Welcome to Pro Scan

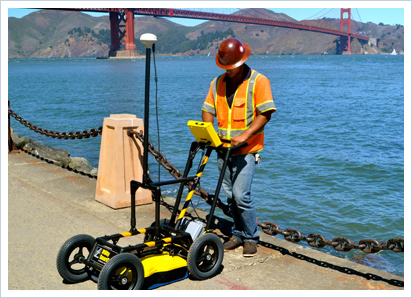

Exceeding our customers expectations is our main goal at Pro Scan. Our friendly staff and highly trained technicians will go beyond to make sure your business with us is always exceptional. With the most advance technology in Ground Penetrating Radar and all of our technicians being in the field of GPR for a minimum of 7 years you can always expect the most accurate results. Call us today and let us exceed your expectations.

Our Services

Experience the magic of your garden at night with our professional garden lighting services. Illuminate and transform your outdoor space today.

CONCRETE CUTTING

- CORE DRILLING

- HAND SAWING

- SLAB SAWING

- CHAIN SAWING

- WALL SAWING

- TRACK SAWGING

- CONCRETE GRIMDING

Why Choose US

With over 50 years of combined experince in ground penetrating radar and concrete cutting, our customers can rest assured they are getting the knoweldge and experience their job requires. With the most advance technology in ground penetrating radar and electromagnetic induction, our highly trained techncians and cutters will help keep your job stay safe and on budget, from any unforseen costly hidden objects.

- Experience peace of mind with our highly trained GPR technicians

- The most accurate markings for post tension cables, conduits, rebar and other costly embedments

- Identify fpl, water, sewer, gas, telecommunications, and other dangerous utilities before you dig or bore

- One-stop shop with real-time results. We will start core drilling the same day

- The most advance equipment in concrete imaging, utility locating and concrete cutting

Benifits

Pro Scan understands that a robust benefits strategy is the cornerstone of a thriving workforce, empowering our employees with comprehensive health, wellness, and career development opportunities.

Pro Scan Industries

Testimonials

Latest Work Gallery

In the bustling urban landscapes of West Palm Beach, Fort Lauderdale, Pompano Beach, and Miami, the structural integrity of buildings and infrastructure …

Introduction: In the bustling cities of Miami, Kendall, Plantation, West Palm Beach, and Boynton Beach, the underground landscape holds secrets crucial to …

Broward County, Florida, with its sprawling urban landscape, is a hub of construction and development. From towering skyscrapers to expansive highways, the …